CPVC

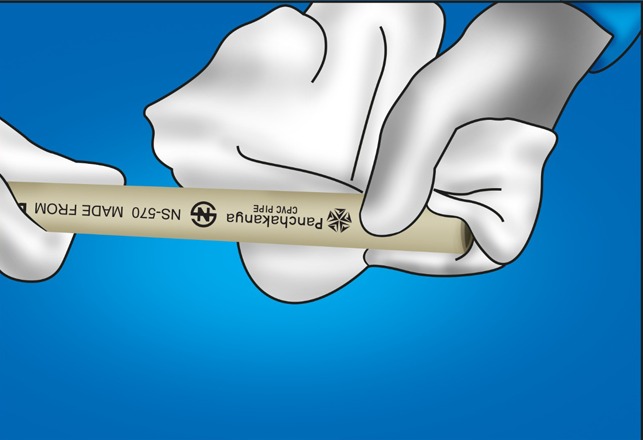

Panchakanya CPVC piping solutions, launched in 2011, represent a premium range designed for hot and cold-water distribution, industrial applications, and agricultural systems. Engineered with high-grade raw materials and advanced international technology, these pipes deliver exceptional performance even under elevated temperatures—outclassing many conventional plastic piping systems.

Versatile. Reliable. Future-Ready

Recommended for both domestic and industrial infrastructure, CPVC pipes are also ideal for solar and electric water heating systems. Their wide application spectrum makes them a robust choice across multiple sectors—from residential plumbing to heavy-duty industrial lines.

Global Innovation, Local Trust

Panchakanya CPVC Pipes are crafted using premium raw materials sourced from Sekisui, Japan — a global leader in advanced polymer technology. Backed by the technical excellence of the Sekisui Chemical Group, every pipe reflects the unmatched precision, durability, and performance synonymous with Japanese engineering expertise.